Credible Actions and Global Solutions

In the face of critical global challenges, such as pollution, resource scarcity and climate change, we are actively committed to making a difference. We have taken a proactive stance toward environmental issues, consistently evolving our approach to enhance our initiatives. Our Board plays a pivotal role by overseeing our sustainability and risk management strategy, including our environmental initiatives. Our operations and facilities are subject to many federal, state, local and foreign environmental laws and regulations. We proactively monitor relevant environmental laws and regulations that impact or have the potential to affect our business, including our operating units.

Our Stewardship

Our corporate-wide environmental policy serves as our guiding framework for addressing critical environmental issues, such as energy consumption, GHG emissions management, water conservation, energy efficiency and management of waste and hazardous materials. We continue to prioritize initiatives aimed at reducing our energy consumption and emissions. We have an established science-aligned GHG emissions target to reduce our absolute Scope 1 and Scope 2 emissions by at least 50%. Looking ahead, we plan to continue focusing on energy-efficient solutions and other environmental initiatives, prioritizing technological feasibility, economic viability and industry best practices. As part of their regular business operations, our operating units have consistently integrated sustainability initiatives into their productivity decisions. Additionally, TransDigm has made substantial investments in efficiency initiatives across our operating units, with a particular focus on improving energy efficiency. Recent operating unit and TransDigm-funded projects include solar panel installations, LED lighting upgrades, HVAC system replacements and other energy conservation upgrades. TransDigm is committed to assisting our operating units as they work to reduce their emissions and minimize their environmental footprints. Looking into 2025, multiple operating units have energy conservation projects planned or already in the works.

Company-Wide Efforts to Reduce Energy and Water Usage

Our Carbon Footprint

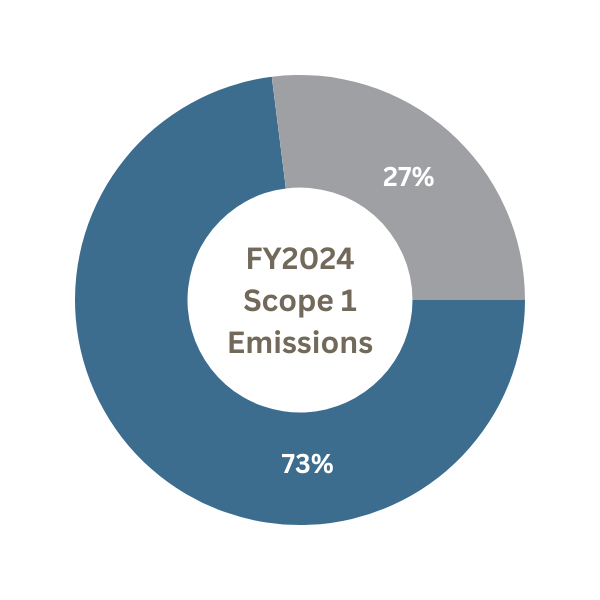

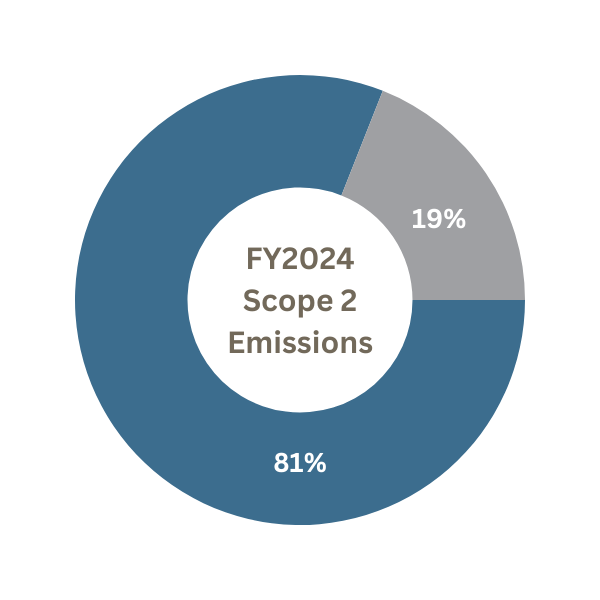

We are dedicated to reducing our emissions and conserving energy, as exemplified by our GHG emissions target—a 50% absolute reduction in Scope 1 and Scope 2 emissions. Our manufacturing processes primarily involve light manufacturing and assembly, with limited heavy manufacturing. Additionally, we predominantly utilize commercial shipping services rather than maintaining a fleet of company-owned vehicles for product distribution. Given our global customer base and the nature of our products, which often entail small shipping volumes, our Scope 1 and Scope 2 emissions remain relatively low. The majority of our GHG emissions result from electricity consumption and the combustion of natural gas. We continue to refine our approach and make corrections as needed to ensure consistency and accuracy across our metrics. For more information and details please download our stakeholder report.

Our Energy & Water Consumption and Greenhouse Gas Emissions

| NATURAL GAS | ELECTRICITY | WATER | |||

|---|---|---|---|---|---|

| Energy (MJ) | GHG (t CO2e) | Energy (MWh) | GHG (t CO2e) | Usage (thousand gallons) | |

| FY2024 | 892,821,589 | 44,947 | 276,783 | 87,920 | 137,791 |

| SCOPE 1 | SCOPE 2 | SCOPE 1 AND 2 | |

|---|---|---|---|

| t CO2e | t CO2e | t CO2e | |

| FY2024 | 51,376 | 87,920 | 139,296 |

Emissions from

TransDigm Base Year

(FY 2019) Operations

Emissions from

FY 2020-FY 2024

Aquisitions